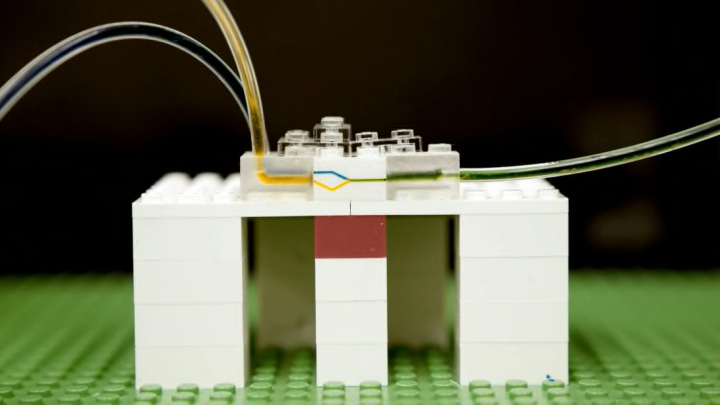

When it comes to microfluidics, precision is everything. Researchers in this field—which analyzes the behavior and control of tiny amounts of fluids— can use a miniscule, flat chip etched with channels (a "lab-on-a-chip") to control the mixing of liquids at a microscopic level. Now, Co.Design reports that MIT scientists have invented a system that achieves the same results using material that most people would recognize: LEGO blocks.

In their study published in the journal Lab on a Chip, the scientists explain how LEGO fits perfectly into their research. They started out carving grooves into LEGO bricks about 500 microns wide—about the width of handful of human hairs—and sealing them with clear film. Next, they built pathways for fluids by interlocking the blocks so the end of one channel lined up with the start of another.

Assembling a custom microfluidics lab this way takes seconds, which is nothing compared to the involved and costly process of building a lab-on-a-chip from scratch. The same blocks used in one configuration can also be deconstructed and rearranged to create a whole new design. As is the case with the traditional chips, the LEGO-based lab can be used in biomedical research to filter fluids, sort cells, and isolate molecules.

The scientists didn't choose LEGO blocks just because they're fun—they're also practical. The plastic toy blocks are some of the most uniform materials available for building modular systems. The molds used in LEGO factories have to meet strict standards, so only 18 pieces of every million created are technically imperfect.

But LEGO toys aren't the ideal building blocks for every microfluidics study. They don't work for experiments performed on the nano-level, and their plastic structure isn't tough enough to stand up to some chemicals. The MIT scientists are looking into developing protective coatings and possibly molding their own LEGOs from stronger materials to open the door to even more research in the future.

[h/t Co.Design]