Time is a 3-D printer’s worst enemy. The machines work by piping out the printed object's material in thin layers, and have to wait for each layer to dry before adding the next one. If they didn't have to wait for the material to dry, a printer could construct items like furniture in a matter of minutes instead of hours. A team at MIT believes they found a way around this issue using giant tanks of gel.

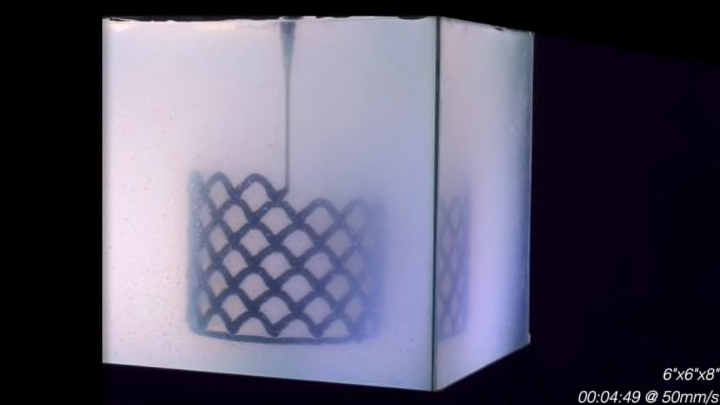

As Co.Design reports, a new technique called Rapid Liquid Printing doesn’t require any layering. Instead, a needle injects the material (either liquified rubber, foam, or plastic) directly into the gel. The gel supports the hot liquid so the machine is able to move on with the rest of the design without waiting for the structure to harden.

MIT’s Self-Assembly Lab developed the technology after they were approached by the office furniture company Steelcase last year. Yuka Hiyoshi, a senior industrial designer for Steelcase, compared the method they landed on to “calligraphy or drawing” when speaking to Co.Design.

The Self Assembly Lab isn’t the first group to come up with a rapid 3-D printing process. The continuous liquid interface production (CLIP) method from Carbon3D uses oxygen and UV light to liquify and harden materials instantaneously. But while that technology is good for printing small, detailed objects in a few minutes, MIT’s printer is ideal printing larger items in the same time frame.

Rapid Liquid Printing works with any item that fits in a vat. Furniture for Steelcase, specifically tops for coffee tables, has been the first big experiment for the printers. Results have been promising, but the company doesn’t plan to integrate the technology into its commercial products just yet. Manufacturing car and plane parts is another possible application for the machine.

[h/t Co.Design]